Laser Plastic Welding is made for medical applications

Today, the laser is an established tool in many areas of production. Due to its high precision, the locally well-dosable energy input and last but not least its cleanliness, this tool has secured itself a firm place in production. Laser plastic welding in particular is particle-free, making it a key technology in the medtech industry.

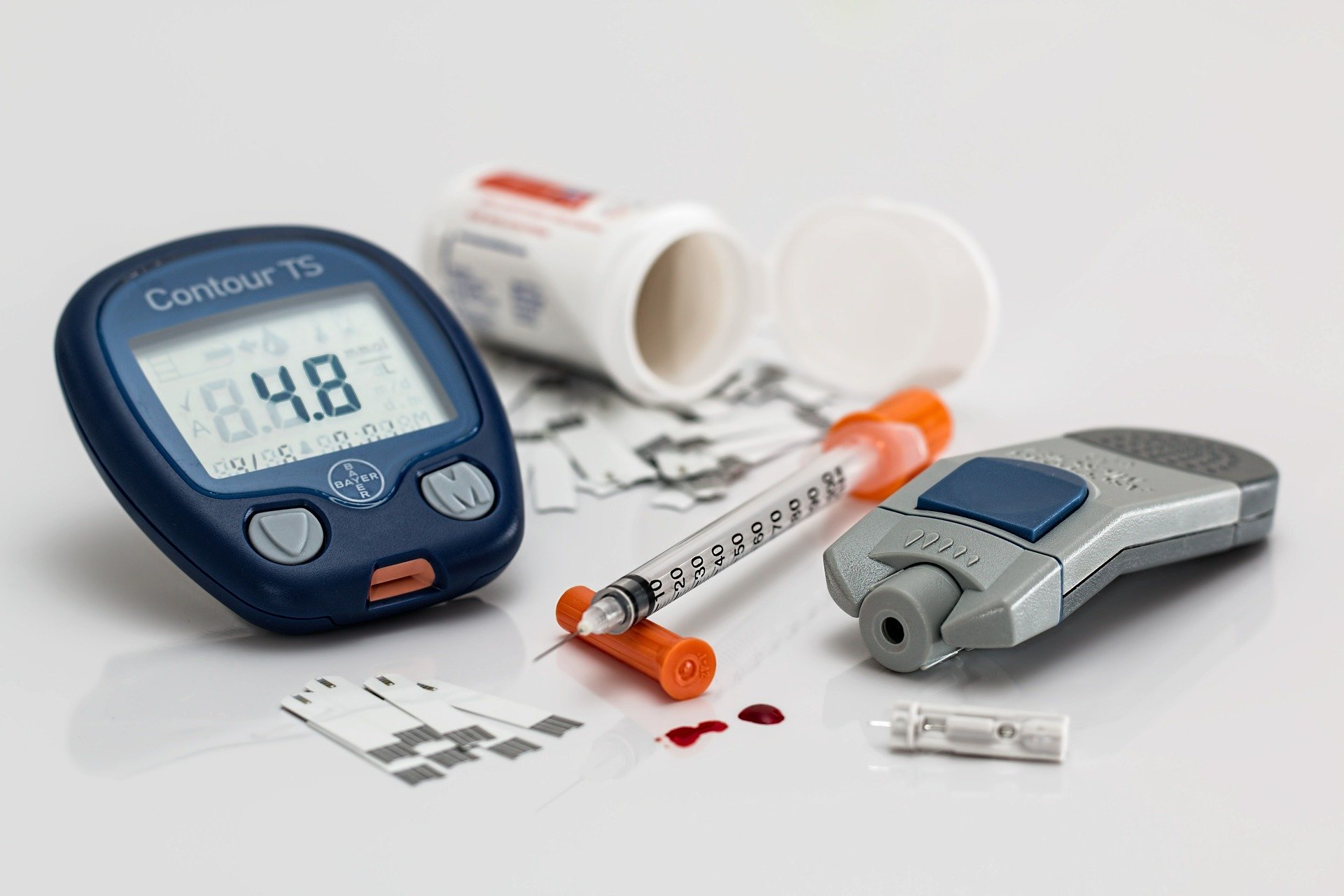

Medical devices and disposables can be manufactured hygienically by means of laser technology. The trend towards smart and highly integrated solutions, especially in the area of point-of-care and drug-delivery systems, requires a high packaging density of the necessary sensitive electronics and mechatronics. For the final assembly of such components, usually only adhesive bonding or laser welding is used. Since the latter is particle-free, clean and free of additives, it is the first choice in this sector.

Laser welding with a wavelength of 2 µm is particularly interesting for medical products, as no absorbing additive is required here. The so-called clear-to-clear welding can be used with many common materials (such as PC, PP, MABS or COC) and is suitable for the production of microfluidics, for example. Also due to the constant development of new treatment methods, the importance of reliable production processes in the healthcare sector is rapidly increasing. A production according to GMP standards can easily be ensured by laser welding of plastics. It offers ideal conditions to master even demanding joining tasks.