Laser welding of high-performance plastics – trouble-free with the right technology

Thanks to their superior properties, such as high temperature and chemical resistance, low weight and dimensional stability, high-performance polymers – such as PPA and PPS – are increasingly replacing assemblies made of metal and conventional engineering plastics. In the automotive industry in particular, this trend is being boosted by the increasing system complexity and integration of functionalities, while at the same time demanding a reduction in installation space and weight.

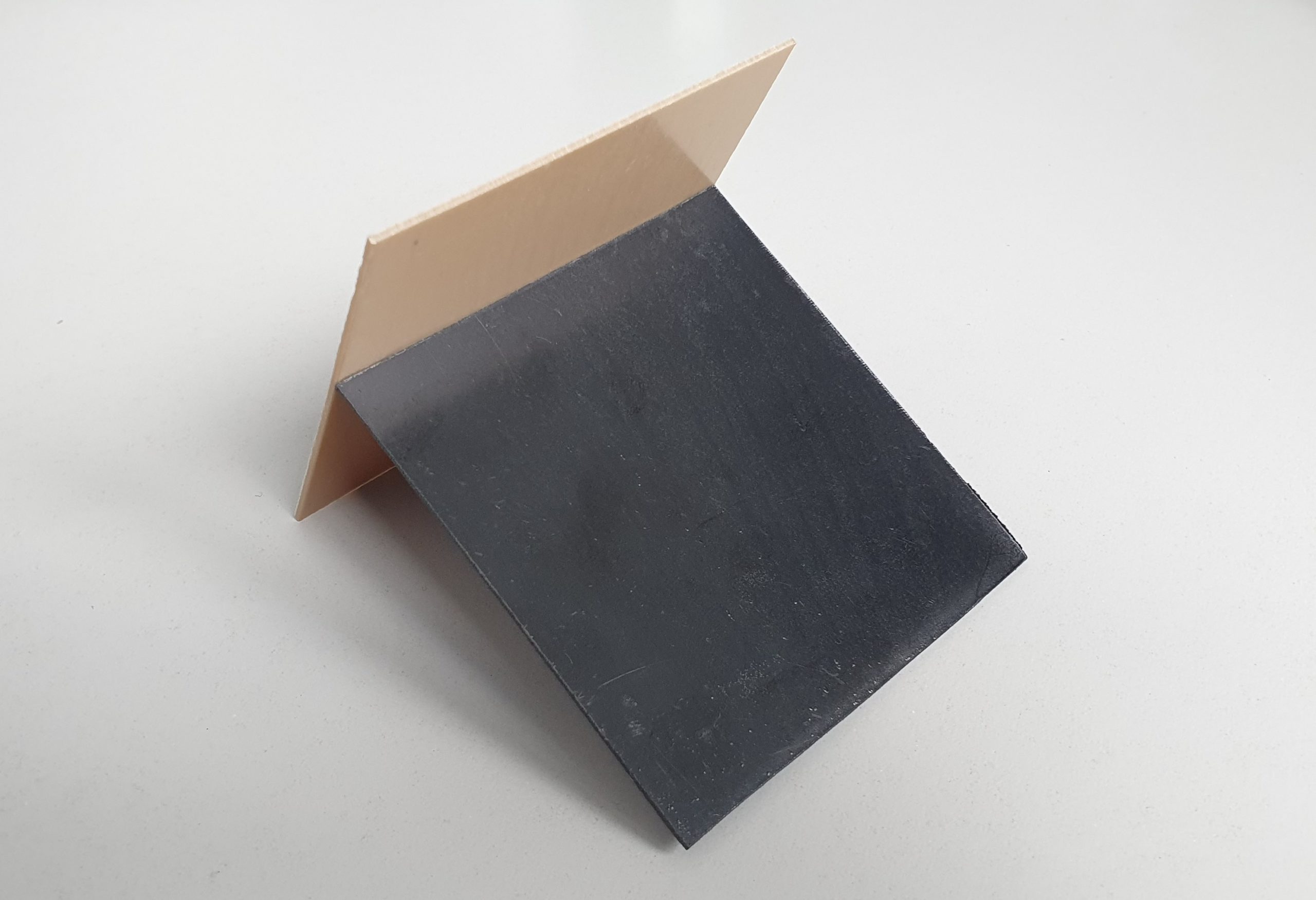

However, the dependence on the optical properties of the joined parts makes laser welding of high-performance plastics a demanding task. This is because they often have a very low transparency for the laser radiation even when unfilled, due to the material properties and pre-processes, for example because of their microstructure.

In order to meet the challenging process conditions, special optical systems, such as the Next Generation Optics (NGO) from Evosys Laser GmbH, can be used for these demanding applications. In combination with special process control, they significantly improve energy input. Due to the much more homogeneous irradiation strategy, undesired effects, such as burns on the component surface at high energy densities, can be eliminated. At the same time, weld seam quality and strength is increased and process time is reduced.

The NGO thus considerably expands the possible applications of laser welding and transfers its advantages to the field of high-performance materials. This makes a significant contribution to meeting the increasing demands for weight reduction, higher packaging and increased cost efficiency.