Advanced Quasi-Simultaneous Welding

Advanced Quasi-Simultaneous Welding, or AQW for short, is a new, patented process. It uses the advantages of conventional laser welding and combines this with the advantages of the EvoClear process for clear-clear welding. As a result, a significant reduction in welding time and improved weld quality can be achieved.

The central process in the AQW process is the established laser transmission welding, in which two plastics are joined in an overlapping arrangement. The laser beam is focused through the upper, transparent joining part onto the lower, absorbing part, where the laser energy is absorbed and converted into heat. The heat transfer then heats the upper joining part as well. Since most engineering polymers have relatively high transmission in a wavelength range of about 800 nm to 1000 nm, a common wavelength of diode lasers often used for laser welding of plastics, they can be used as transparent joining partners. By adding additives such as carbon black, the laser absorption parameters for the lower joining part can be adjusted.

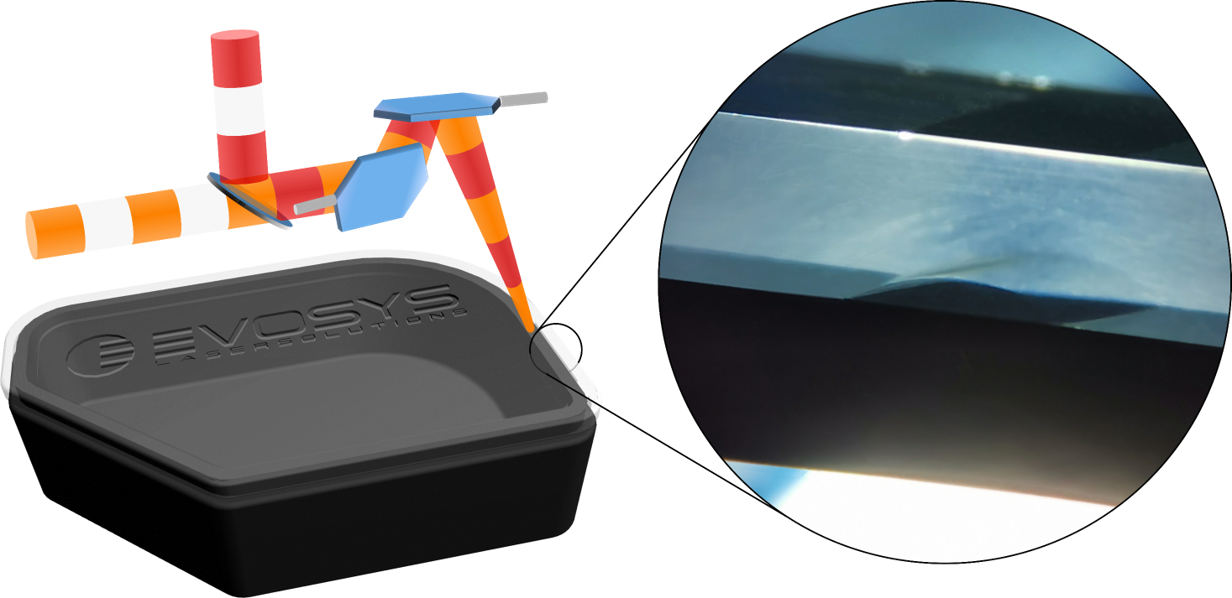

The high dependence of the process on heat transfer from one joining partner to the other entails various disadvantages. The parts must have high geometric accuracy to ensure perfect contact. This is a particular problem in contour welding, where the laser moves only once along the weld path, since air gaps can hardly be bridged here. The absorption of energy, especially in the absorbing part, also leads to a high temperature gradient between the two parts during the welding process. Particularly when welding highly transmissive, amorphous polymers such as polycarbonate (PC) or polymethyl methacrylate (PMMA), a high temperature gradient is formed, which leads to residual stresses in the joining area, restricts the process window and thus increases the processing time. To compensate for these disadvantages, the AQW process supplements the primary laser radiation with a second laser source with a different wavelength. This secondary radiation, usually in a wavelength range above 1.5µm, aims to heat the upper joining part directly and not only by heat transfer. This reduces the temperature gradient and increases the process window. In the AQW process, the workpiece is not irradiated simultaneously, but alternately with two laser sources. In contrast to simultaneous irradiation, this strategy and a targeted selection of the wavelengths used allow a selective amount of energy to be introduced into each joining partner. By switching between the two laser sources in a specific time pattern, the process can be better controlled and adapted to the desired process results. The use of a laser as a secondary radiation source also facilitates integration with commonly used beam delivery systems, such as galvanometric scanners, which is particularly important in a quasi-simultaneous welding process.