Design layout of the joining zone – Part 1

An essential component for a robust process is the design of the joining zone. Basically, a distinction can be made between process-independent and process-dependent criteria. The following criteria and information are generally valid for all process variants.

MATERIAL THICKNESS – Depending on the material used for the laser-transparent joining partner, the material thickness in the area in which the laser radiation passes through the transparent component should not be excessively thick. It has proven to be a good guide value that the material thickness is selected similar to the planned width of the weld seam. As a rule of thumb, however, the thinner the better! Due to the large number of different materials and the variety of colors and fillers, it is always advisable to consult an experienced specialist from EVOSYS and to carry out transmission measurements to estimate the weldability.

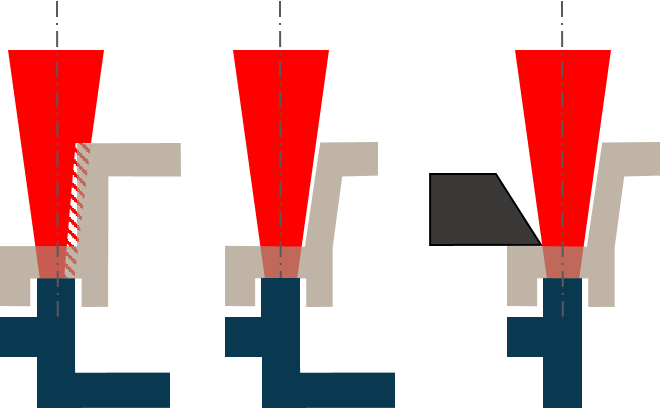

ACCESSIBILITY – Due to the characteristic beam shape of the usually focused laser beam, it is necessary to provide shadow-free access in the area above the joining zone.

SURFACE FOR FIXTURE – An essential component of the laser welding process is the joining force between the two joining partners. The use of a clamping device is required to apply this force to the components to be joined. Usually, a force application is required in close proximity to the entire weld seam. Sufficient space must be provided in the area of the joining zone to support the corresponding clamping device and to ensure accessibility for the laser beam. The applied force usually moves in a range of 2-5 N/mm^2 relative to the weld seam surface. An appropriate counter bearing for absorbing the applied force must also be provided. In most cases, this is done directly via the component and a component support which follows the shape of the overall assembly.