Laser transmission – quality can be measured

The laser welding of plastics is dependent on a laser-transparent and laser-absorbing joining partner, which are connected in an overlap weld. While the absorbing properties are usually robustly adjusted by additives and other influences play a minor role, the laser transmission reacts sensitively to various factors. These are, for example, the material and its microstructure, the component geometry and material thickness, the addition of additives (such as colorants, glass fibers, nucleating agents, flame retardants, etc.), storage conditions and aging or the parameters of preliminary processes, such as the mold and melt temperatures in injection molding. If these influencing variables vary, this can lead to fluctuating laser transmission and thus weld seam quality.

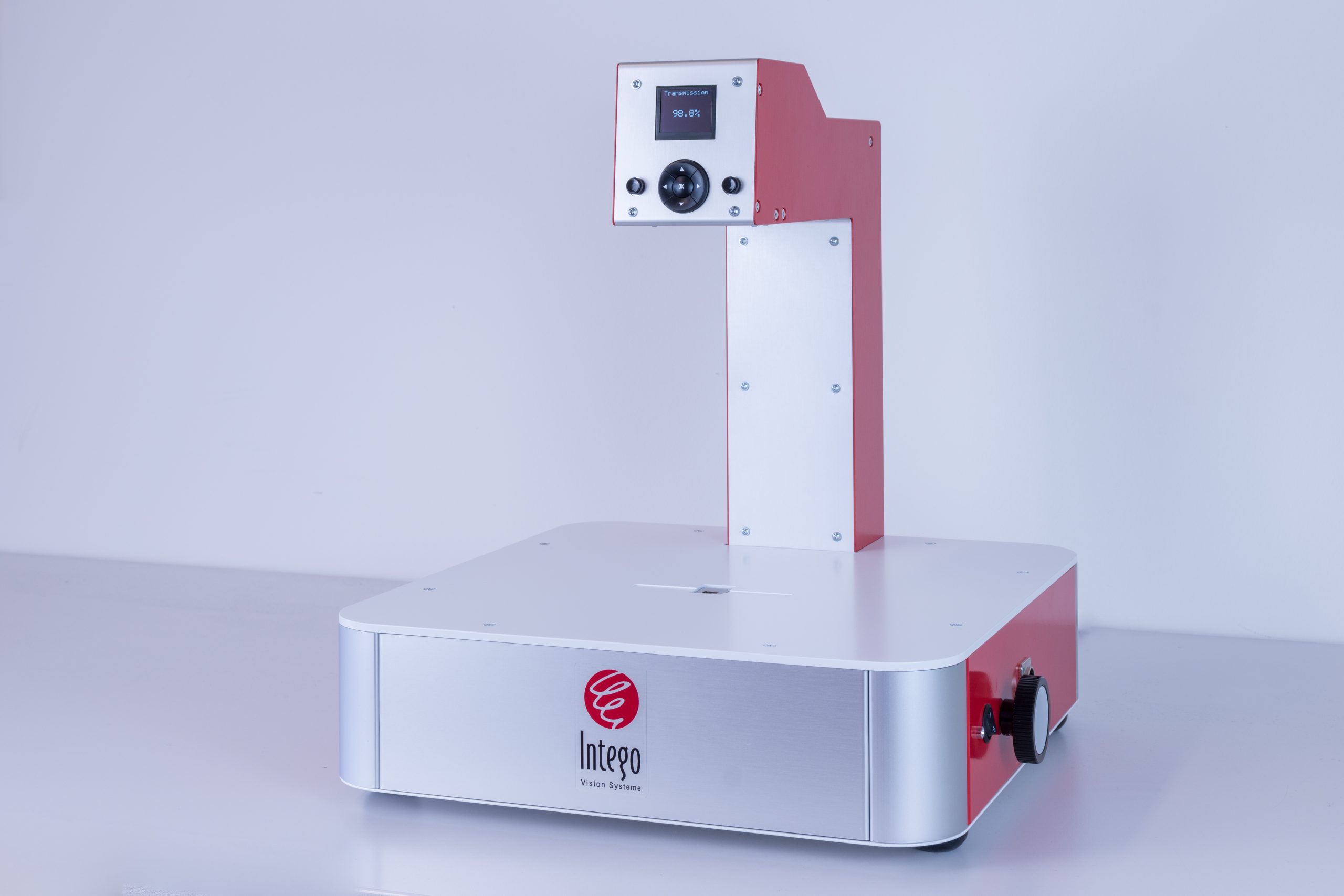

In order to ensure a batch-independent, constant transmission of the laser-transparent components, transmission measurement devices such as the innovative TMS from Intego GmbH can be used in quality assurance. These are available for flat parts (TMS Planar) as well as for radial symmetric assemblies (TMS Radial). They are designed either as a simple and intuitive to use tabletop system, but can also be integrated inline into the production process for an automated measuring sequence. The TMS devices are undergoing a complex calibration process, so that a high reproducibility and comparability of the measurement results is given. This is important if, for example, several systems are to be used at different points in the value-added chain, such as after the injection molding process and before the joining operation.

In addition to the well-known, reliable methods of process control, the transmission measuring devices of Intego GmbH thus make a further contribution to ensure the high seam quality of laser welded joints.