Laser welding of thermoplastic elastomers

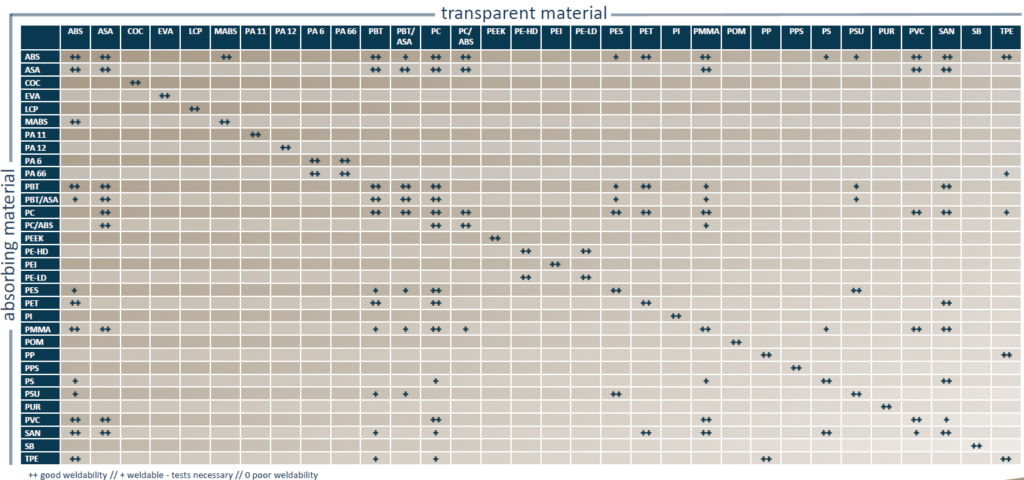

Thermoplastic elastomers (TPE) are a group of plastics that exhibit rubber-elastic properties. Unlike the conventional, chemically wide-meshed crosslinked elastomers, their polymer chains are embedded in a thermoplastic matrix. The physical crosslinking points dissolve reversibly under the influence of heat without the macromolecules decomposing. As a result, the processing methods of…