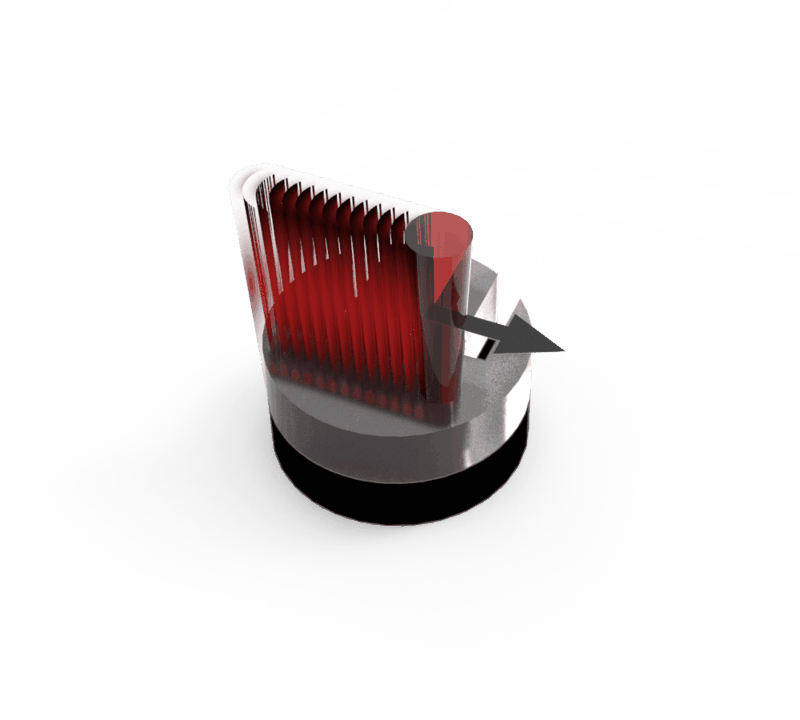

Quasi-simultaneous welding

In so-called quasi-simultaneous welding, the weld seam is repeatedly scanned at high speed with a focused laser beam. The feed rates are usually above 300mm/s up to several meters per second. All areas of the weld seam are heated and melted almost simultaneously (i.e. quasi-simultaneously). Due to the simultaneous melting of the entire weld contour and the clamping force applied by the clamping technology, the two components to be joined move towards each other and melt is expelled at the side of the weld seam. This joining path serves to compensate for component unevenness and can also be used for process control.